Delivery of petroleum products

Reducing the cost of delivery of each liter of petroleum products from the tank farm to the gas station.

Optimization of routes for fuel trucks and automatic planning of delivery routes.

Purpose of system implementation

Save on the number of vehicles required for the delivery of petroleum products.

Minimize the mileage of vehicles in the process of delivery.

Select the optimal fleet of fuel trucks according to technical and economic characteristics.

Reduce the cost of maintaining the existing fleet of fuel trucks.

Tasks to be solved

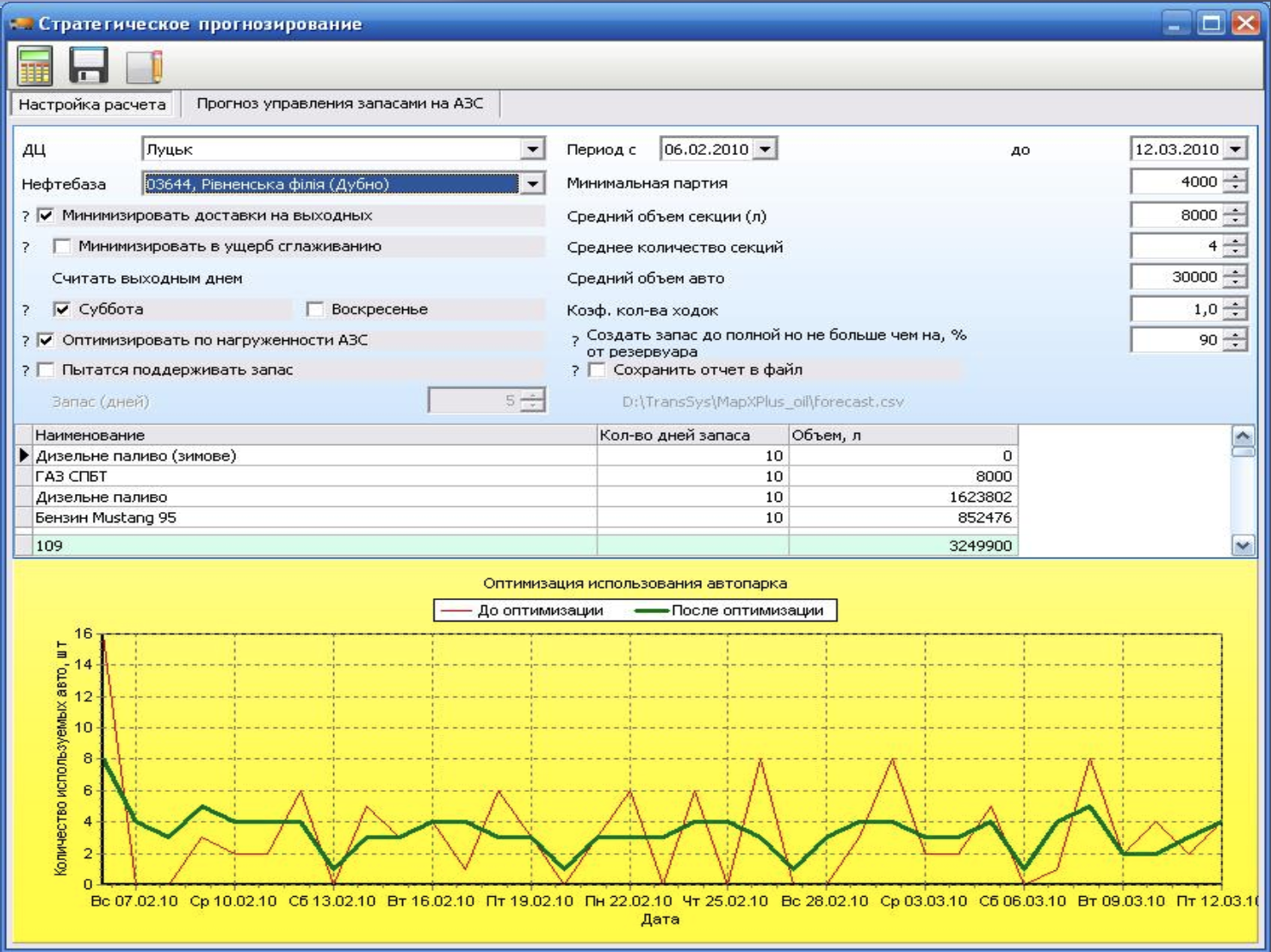

Forecasting filling stations in petroleum products, making orders according to the chosen strategy, optimizing stocks.

Optimization of routes for fuel trucks when delivering oil products to the gas station network, reducing the cost of delivering each liter of fuel from the tank farm to the gas station.

Optimization of the fleet of fuel trucks, monitoring of movement on the delivery of petroleum products.

Monitoring the consequences of an accident at gas stations.

The models used allow us to reduce the cost of delivery, reduce the amount of consumables, and reduce the delivery time.

Intelligent control

Centralized or regional planning management. Zoning and objects of responsibility of each control center are customizable.

Forecasting the needs of gas stations / filling stations in petroleum products for a given planning period (work shift, day, week, month, etc.) taking into account the days of the week, seasonality and resource turnover for each facility and type of fuel.

Forecasting and providing calculated data on the needs of the network of gas stations / filling stations as a whole to optimize the stocks of petroleum products at the company's oil depots for a given period of time.

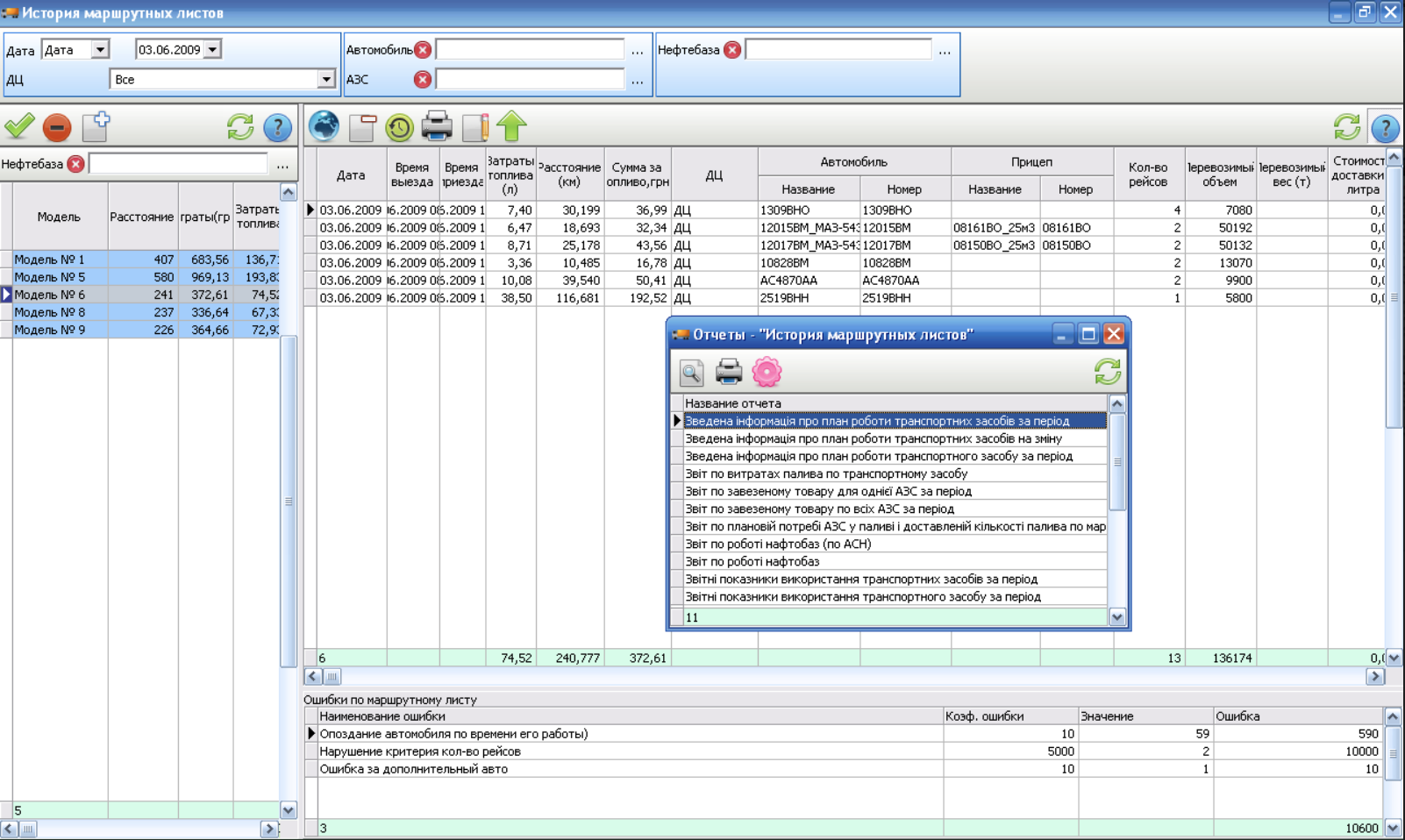

Prompt formation of route sheets (scheduled tasks) for each vehicle for a work shift for the delivery of light oil products to customers (gas stations / filling stations and others).

Optimal planning

Planning long-term vehicle routes for a given number of work shifts, taking into account the requirements of the Labor Code and the internal regulations of the enterprise regarding the time of movement / rest of drivers, stops along the way (refueling vehicles, meals for drivers, etc.).

Formation of orders for the delivery of petroleum products to customers, both on the basis of the forecast, and in manual mode.

Calculation of planned and actual costs for the delivery of petroleum products to customers by our own vehicle fleet.

Calculation and evaluation of the feasibility of using third-party hired fuel trucks.

The use of electronic vector maps, with the ability to edit the road network, create new roads and close existing ones (for example, in case of repair), interchanges, take into account traffic capacity during the day and days of the week, direction of movement, speed limits, etc.

Binding of control objects (gas stations/filling stations, tank farms, third-party clients) to vector maps, taking into account the rules and restrictions.

Resource control

Monitoring the compliance of planned routes and vehicle movement parameters (driving speed, travel time, loading oil products at an oil depot, unloading at a customer’s, etc.) in real time using a GPS monitoring subsystem (integration with an existing one, or delivery as part of a solution) . Signaling to the dispatcher about deviations from the specified traffic parameters for prompt response.

Customizability of the rules for changing the types of petroleum products in the sections of fuel trucks. For example, after transporting diesel fuel, it is not allowed to fill in gasoline in the same section.

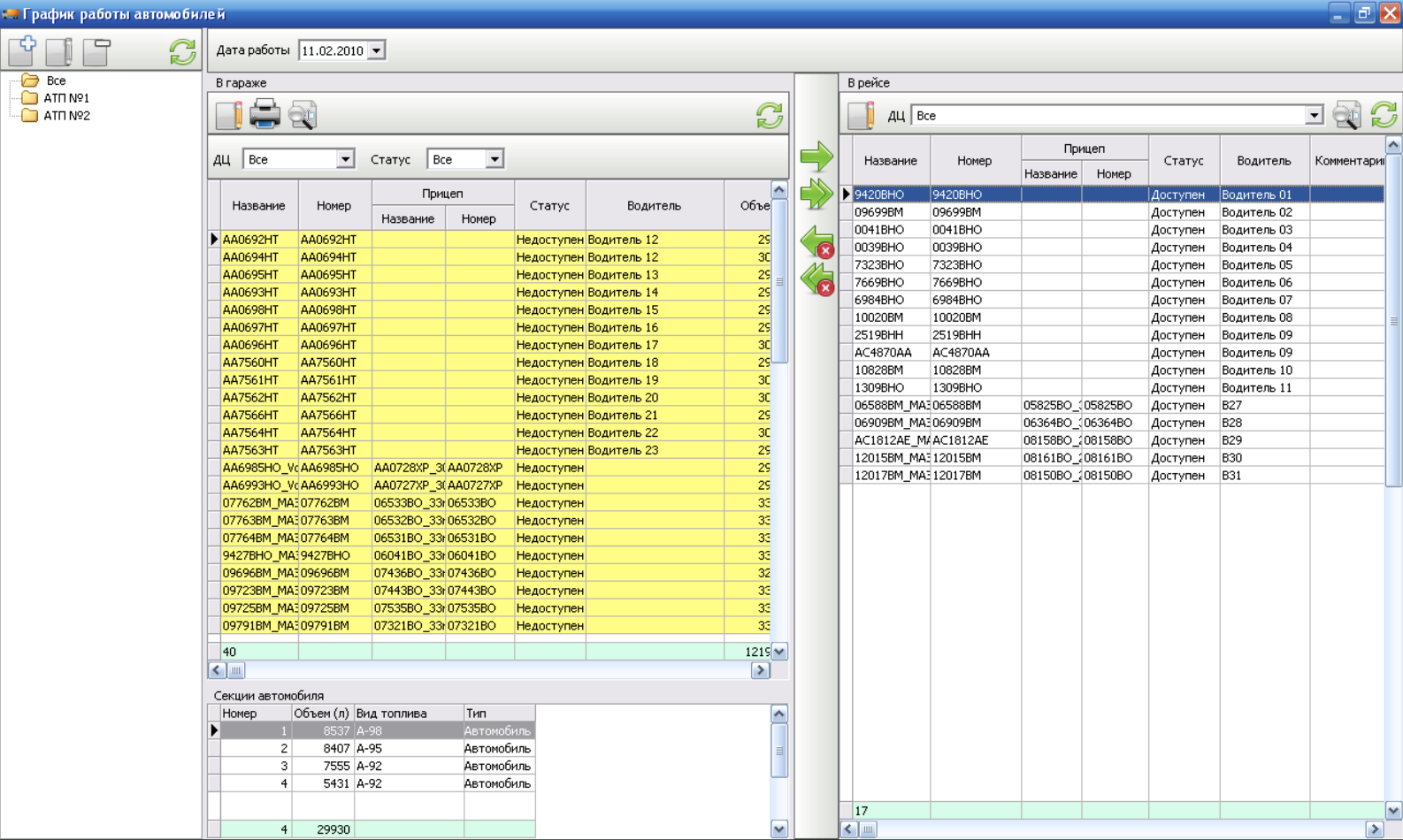

Accounting for scheduled maintenance of vehicles and shift availability.

Simulation of various situations of development of events. For example, when expanding the network of gas stations/filling stations in new regions, the calculation of the need for the optimal number of fuel trucks, taking into account a number of features and parameters.

Managing the queue of vehicles when loading oil products in the section of fuel trucks with traffic routing between ACH in the loading area of the tank farm, including the calculation of the arrival / departure time, organizational delay time and the speed of loading oil products in the section.

Full automation

Automatic distribution of notifications to participants in the process of delivering petroleum products (drivers of fuel trucks responsible for receiving petroleum products at gas stations/filling stations and shipping petroleum products at oil depots, dispatchers, etc.).

Integration with external information systems (automated control systems for filling stations/filling stations, automated control systems for loading oil products from tank farms, various accounting systems).

The system can be additionally equipped with equipment for monitoring actual residues (SMR) in the tank farm of gas stations/filling stations (if there is an installed measurement system), which will allow obtaining accurate data on oil product residues immediately before calculation.

Differentiation of access rights (editing, viewing, deleting, printing) to certain parameters and functions of the System, depending on the functional duties of the personnel.

Formation of various reports on the results of planning for the selected period, to control the specified key performance indicators, as well as other necessary for work.

Everything is taken into account, everything is under control

It is unacceptable that a gas station/filling complex does not have any type of oil products from those declared on the stele (if there is an available stock at oil depots).

The route of movement of vehicles is allowed only on roads agreed in advance with the Police.

Fuel tankers are divided into sections of different sizes. The capacity of the sections can change over time by 10-100 liters. Each section is calibrated approximately once a year.

Each tank section can have only two states - full or empty - intermediate states are not allowed.

Accounting for transported petroleum products is carried out by volume and weight.

If the fuel truck has a trailer, then the trailer tank is unloaded first of all, and already with an empty trailer it is allowed to unload the sections of the fuel truck from the end to the beginning.

Accounting for ACH types at oil depots: top, bottom, combined loading; single-sided single/double, double-sided single/double.

Topology of ASN location in the shipping area of each tank farm.

Accounting for restrictions on the possibility of vehicles entering gas stations / filling stations according to geometric parameters (for example, the length of a driveway).

Contact Us

Fill out the form and our team will contact you within 24 hours.